Harvesting fruits: the technological evolution of this process

Alimentos SAS • Dec 23, 2021

Raw material quality is paramount to food production. Keeping this in mind, so is harvesting fruits correctly. In this article, we explore the traditional methods to do it, as well as the more recent, innovative ones.

Why is harvesting fruits correctly so important?

As mentioned, the state of raw food is pivotal for food businesses. For instance, the food-processing industry has it easier when the materials they receive are in good condition. Similarly, producers down the line in the supply chain benefit from high-quality direct materials.

Harvesting fruits correctly is critical to making safe, alluring, consumable products. On the one hand, adequate practices contribute to the ideal alignment of raw materials depending on how people consume the final product.

For example, the food’s selling and consuming times directly influence the proper time to remove fruit from its plant or tree. Some need to be picked as ripe fruit, while others are collected before ripening so they can be stored for longer (Childers, n.d.).

On the other hand, optimal harvesting processes also lead to intermediate goods that directly contribute to the quality of final products. When farmers collect fruit correctly, they manage to minimize damage conducive to spoilage. This is the case for bruising, which tends to make fruit more susceptible to infection from molds, or bacteria growth (Michigan State University, 2016).

So, top-quality fruits can become versatile ingredients in the food industry, like purees. Typically, they are processed sound ripe fruit (JBT, n.d.). Purees are popular components of baked goods, dairy products, beverages, confectionery, baby food, jams, and jellies (Allied Market Research, 2021). Manufacturers favor them because they tend to retain flavor and nutrients from fresh fruit while being more efficiently handled (Dohler, n.d.).

Methods for harvesting fruits

We have highlighted the importance of correctly harvesting fruits. Now, let’s take a look at the different methods available to achieve it.

Manual harvesting

In this traditional method, there are two variants (Megan, 2019):

- Farmers collect the produce by hand, without any tools.

- Farmers pick the produce using hand tools, like clippers.

Machine harvesting

In this more advanced method, farmers can collect fruit with the aid of specialized machines. These are some of the leading machines that are harvesting fruits today (Childers, n.d. Feucht Obsttechnik, n.d.):

- Fruit harvesting machines efficiently collect fallen fruit from the trees. Farmers can operate them mechanically or ride them.

- Tree and bush shakers remove the fruit and handle it with catching belts, bins, pallets, and electric lifts.

- Sweepers and blowers have cleared fallen fruit from the fields so that farmers can pick them up with other machines.

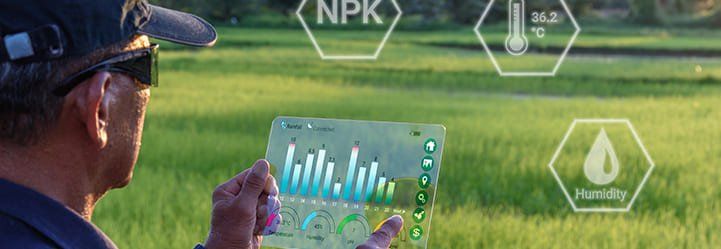

In any case, these machines need the help of humans to function. Such a requirement becomes an issue as the agriculture industry grows more and more inclined to pursue labor-saving and bigger-scale efforts (Onishi, et. al., 2019). As a result, innovation in the industry is steering toward technology applications that automate agricultural tasks.

How technology is changing our methods of harvesting fruits

Automatic harvesting by robots involves two main tasks. First, the system detects the fruit on the tree or plant by computer vision, usually with a sensor. Second, collecting fruit without damaging it or the source using a robotic arm with the correct motion (Onishi, et. al., 2019).

Today, researchers are working to create affordable robots that can successfully pull fruit from trees with an efficiency similar to humans. A prototype from Australia’s Monash University Department of Mechanical and Aerospace Engineering needs seven seconds to harvest an apple. A human takes between four and five (Treloar, 2021).

Already, there are working robots picking fruit in fields. For example, Agrobot uses real-time artificial intelligence to assess fruit ripeness and determine whether to harvest it or not. It also has short-range integrated color and infrared depth sensors to capture product details (Mashable, 2019).

Moreover, it has up to 24 robotic arms that can work independently from each other. They grip and cut the strawberry stem and place the fruit into containers. Agrobot could harvest 20 acres in three days (Mashable, 2019).

While there are proven techniques to make the most of produce (like preserving fruits and vegetables), correctly harvesting it does make a difference in successfully allocating quality goods in the food supply chain. Automation seems to be the leading technology trend in the future of this critical process.